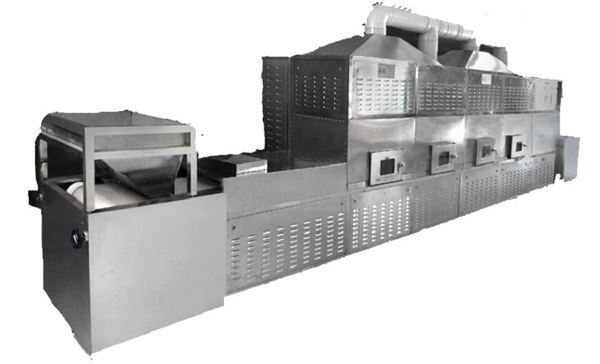

Tunnel Microwave Dryer Machine

Tunnel Microwave Dryer Machine

TUNNEL MICROWAVE DRYER MACHINE G-50

COOLING METHOD : WATER COOLING TYPE

Tunnel Microwave Dryer

Heating Method: Microwave drying

Design and manufacturing conditions and technical specifications:

- Control Mode:Automatic PLC control and touch-screen LCD display image

- Total Power:100 KVA

- Temperature during the operation:≤80℃

- Total Capacity:1500 kg/hr to 2000kg/hr

- Worker:1~2

- Equipment weight:About 5000 kg

- Equipment system components:

a) The microwave drying chamber system

b) Microwave leakage suppression system

c) Heating chamber heat preservation and heat insulation system

d) Material transport system

e) Independent control and detection systems

f) Independent exhaust systems

g) Independent heat system

h) Automatic feeding system

i) Material cooling system - Operating environment:

a) Input power:Three-phase and five-wire 380V±10% 50Hz±1%

The zero line and the line thickness with the same specifications.

b) Surrounding non-corrosive gases, conductive dust and explosive gases.

c) Environment temperature:-5~45℃

d) Relative humidity:≤80% - Microwave system

a) Microwave frequency:2450±50MHz

b) Microwave output power:≥100kw.

c) Microwave heating chambers quantity:8

d) Microwave heating equipment dimension(LxWxH):19400×1700×2200mm

Conveyor width:960mm

Conveyor standard:The cloth belt(Food Grade)

e) Microwave heating chamber is made of 2.0mm thick stainless steel plate.

Equipment racks, and power supply box are designed and manufactured of 1.5mm stainless steel skeleton.

f) Microwave fed parts: the top of the feed-in。

g) Minimum isolation between the feed ports: more than 20db

h) Bobby settled microwave feed: less than 2 (at rated load)

i) Microwave feeding and discharging opening height:50mm

j) Cooling type: imported water-cooling magnetron, special electronic power transformer.

k) Microwave operating modes: standard rectangular wave guide.

l) Delivery forms: conveyor + Frequency

m) Equipment delivery system installed metal detector function.

n) Install strengthen magnet to remove iron grits from the materials. - Microwave Leakage: The national standard GB10436-89

In line with national GB16798-1997 hygiene of food machinery safety indicators

Comply with electrical safety standards GB5226