CTC Machine

Gimpex Teaman Jumbo And Standard Ctc Machine

Frame Construction :The solid cast iron frame imparts rigidity to the cutting unit and makes it vibration free. This unique construction ensures alignment of rollers over a period of time and eliminates parallelism related problems.

Housing Blocks Cartridge Bearing System : Completely sealed and compact bearing housings. Both ball and roller bearings are encased in solid precision machined steel shell with bearing seals. The bearing cartridge system eliminates problem of frequent mounting and dismounting of bearings during life as well as greatly improves ease of roller changing operation. This ensures longer bearing life as well as greatly improves ease of roller changing operation.

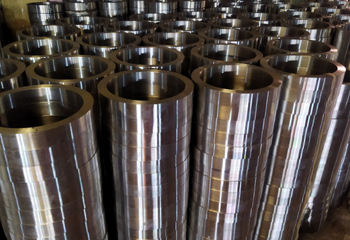

Segments Rollers: Identical Slow speed and High speed rollers, interchangeable with each others.

Auto De jamming Mechanism: Sophisticated mechanism which automatically releases the rollers in the event of a jam and can be reengaged instantly to preset position.

Microdial: In built heavy duty Micro dial mechanism on both sides. Dial nut with graduation to ensure correct engagement between segment rollers.

Micromesh Controller : An in-built synchronised mechanism which helps in finer adjustment.

Axial Adjustment : Single point axial adjustment for easy roller meshing.

Positive Drive : Specially designed sturdier helical gear box with twin output shafts drives machine rollers with heavy duty propeller staffs. The Drive system minimises transmission losses and ensures optimal utilisation If power.

Roller Lifting Spillage Tackle: In-built bracket with each cutting unit and one lifting tackle is provided for easy removal or refitting of the segment rollers from the machine.

Moving Cover: In this latest technology of moving cover, no lumps are deposited enabling opening out for inspection, reduces bacterial contamination and improves general hygiene of the machine.

Centralized Air Cooling System:

Recommended for jumbo machines only, this helps in quick dissipation of heat and keeps leaf cooler to enhance liquor quality.

Technical Specification:

| MODEL | JUMBO 13”Teaman 764-30” | JUMBO 13”Teaman 914-36” | 9.1/2” & 8.1/2”Teaman 764-30” | 9.1/2” & 8.1/2”Teaman 914-36” |

| UNIT | 3 Cut 4 Cut | 3 Cut 4 Cut | 3 Cut 4 Cut | 3 Cut 4 Cut |

| OVERALL DIMENSIONS | ||||

| Length (mm) Width (mm) Height (mm) Output W/L | 10481 13122 2245 2245 1090 1090 1000-1000 kg | 10481 13122 2400 2400 1090 1090 1100-1200 kg | 9908 12346 2245 2400 1040 1040 800-900 kg | 9908 12346 2400 2400 1040 1040 1000-1100 kg |

| RECOMMENDED HORSE POWER (HP) | ||||

| Normal Hard Cut | 20-15-15-1525-20-20-20 | 25-20-20-2030-25-25-25 | 15-15-15-1520-15-15-15 | 20-15-15-1525-20-20-20 |

| PVC IMPORTED CONVEYOR BELT | ||||

| Main Conveyor | Width Length(in mm) (in mm) | Width Length(in mm) (in mm) | Width Length(in mm) (in mm) | Width Length(in mm) (in mm) |

| Feed Subsequent Cut Moving Cover | 900 4876 900 6096 900 2030 | 1050 4876 1050 6096 1050 2030 | 900 4876 900 5790 900 1830 | 1050 4876 1050 5790 1050 1830 |

Belt can be provided short or long as per requirement and space availability Discharge belt length may vary as per requirement. Extended discharge can be provided on request.